Current location:Home / Product / Sampling valve / SQM-Q Pneumatic Sterile Sampling Valve

application

The sterile sampling valve is mainly used for collecting material samples from tank equipment or pipelines, and requires sterilization treatment before and after each sampling. No dead corners, thorough sterilization, continuous and sterile sampling at any time. Widely used in industries such as food, brewing, beverages, dairy products, toothpaste, cosmetics, biopharmaceuticals, etc.

technical parameter

Specification: DN15

Connection method: welding, clamp, thread

◆ Air source pressure: 0.5-0.7bar

Maximum working pressure: ≤ 8bar

Maximum sterilization pressure: ≤ 3bar

Working temperature: -10 ℃ to 120 ℃

◆ Maximum sterilization temperature: 120~150 ° C:

◆ Part in contact with materials: SS316L Other components SS304

◆ Internal surface contact product: Ra ≤ 0.4 μ M

◆ Sealing element: PTFE

operational principle

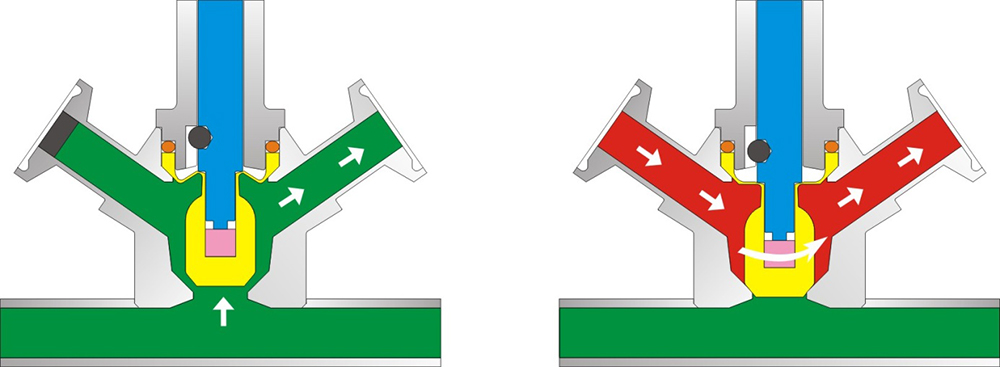

This sterile sampling valve is mainly divided into pneumatic components, handles, valve bodies, and diaphragm sealing rings. When in the closed state, the valve core is pushed by the spring tension, and the sealing head is pressed tightly by the valve core at the inlet of the valve body material to achieve sealing effect; If sampling is required, steam or other sterilization medium is introduced from one (usually the lower) sampling port to fill the entire sample chamber and export it from the other sampling port. After a certain period of action, the sample chamber and sampling port are kept in a sterile state; Then, by feeding air or lifting the handle, contracting the spring and loosening the valve core, the sealant head is detached from the material inlet of the valve body, allowing the sample to flow out of the tank through the sample chamber and be collected from the sampling port; After the sampling is completed, turn off the air source or lower the handle, loosen the spring, and press the sealant head onto the material inlet of the valve body again through the valve core; Inject clean water to discharge the residual liquid in the sample room (if the sample is a clean medium such as sterile water, this step can be omitted), and then inject sterilization medium for sealing and retention until the next sampling.

Schematic diagram of working principle

Schematic diagram of sampling status and sterilization status

Related Information